How solar panels use light from the sun to create power. Photovoltaic (PV) cells made of silicon are used to make solar panels. Here is the ideal solar panel choice for your home or factory.

The sun’s rays fall on the PV cells and remove electrons from their atoms. Electricity is produced by PV cells as electrons move through them. After passing through an inverter, the electricity is converted into AC energy that can be used in factories or homes.

There are three primary types of solar panels available for residential use. They are thin-film, mono-crystalline and polycrystalline.

The appropriate solar panel type for your installation will depend on your tastes and circumstances unique to your own property, as each type has particular benefits and drawbacks.

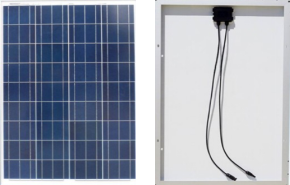

Polycrystalline silicon solar cells were created in the early 1970s when there was the first oil crisis. Low cost alternatives were suggested to make polycrystalline cells that were low cost and based on silicon as the PV industry was constrained in many applications. Polycrystalline silicon is the main raw material for manufacturing conventional solar cells in the crystalline silicon-based photovoltaic field. PV (Solar Panel) producers used more than half of the world’s poly silicon supply for the first time in 2006.

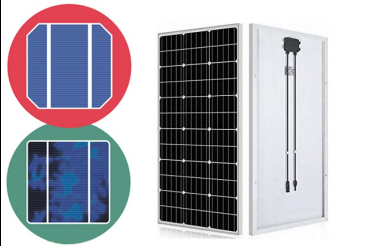

B) Mono-crystalline Solar Panel

In 1941, the first mono-crystalline solar cell was made. A technique for producing mono-crystalline silicon that could produce mono-crystalline solar cells was discovered in 1918 by Polish researcher Jan Czochralski. The base material for the silicon-based discrete components and integrated circuits used in nearly all contemporary electronic devices is mono-crystalline silicon. In addition, mono-Si is used as a photovoltaic, light-absorbing material to make solar cells.

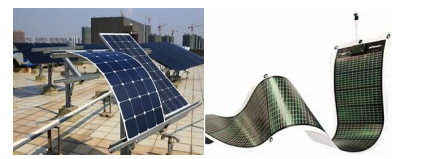

On a substrate such as glass, plastic, or metal, one or more thin layers of photovoltaic material, or thin film (TF), are deposited to form thin-film solar cells. The 1970s saw the development of thin film solar cells. A thin layer of cadmium sulfide (CdS) was placed on a glass substrate to form the first thin film solar cell. A thin layer of copper sulfide (Cu2S) was then applied over the CdS layer to form a p–n junction.

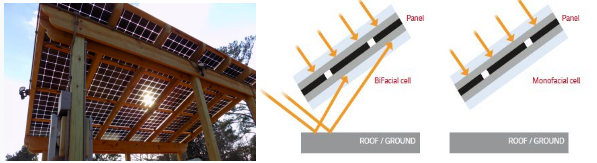

Bifacial panels can capture sunlight from both sides, which increases their energy production efficiency. They can be either monocrystalline or polycrystalline and are usually installed in elevated positions or on reflective surfaces to maximize their efficiency.

Solar roof tiles or solar shingles are designed to resemble traditional roofing materials while generating electricity. They offer an attractive option for home owners who want to seamlessly integrate solar power into their roofs.

Mono half-cut solar panels are made by cutting a standard cell in half and connecting the two halves in series. Because they have reduced resistance loss and can produce more power under low light conditions, semi-cut solar cells are more efficient than conventional cells.

Mono-crystalline solar panels, which are made from a single silicon crystal, are more efficient than polycrystalline solar panels. Due to its construction from multiple silicon crystals, polycrystalline solar panels are less expensive than mono-crystalline ones. Mono-crystalline solar panels are black and appear uniform, while polycrystalline solar panels are blue and appear speckled.

Traditional mono-crystalline solar panels are split in half to make a half-cut solar panel. Using a laser, the cells are split in half. Half-cut panels often use PERC technology, which provides greater module efficiency, and features 120 to 144 cells. The square-shaped cells split down the middle, producing twice as many cells only half as large as the original square cells.

The amount of sunlight that is turned into energy determines the efficiency of a solar panel. The power output of a solar panel is calculated by dividing the amount of sunlight falling on the panel by that amount. Temperature, shading and orientation are just some of the variables that have an impact on solar panel efficiency.

| Particulars | Mono-crystalline Solar Panels | Polycrystalline Solar Panels |

| Cost | High | Low |

| Efficiency | High (19-21%) | Low (15-17%) |

| Appearance | These panels have black or dark blue hues with octagonal shape | These panels have blue hue with square edges |

| Temperature coefficient | Lower (0.35% per degC) | Higher (0.4% per degC) |

| Annual Degradation | Lower (0.55% per year) | Higher (0.7% per year) |

| Lifespan | 25+ years | 25+ years |

| Advantages | Heat-resistant and energy-efficient, progressively reducing the production of power. | Reasonably priced Minimal waste during production Minimal carbon footprint. |

| Disadvantages | costly with a large carbon footprint | Reduced energy efficiency and poor heat resistance |

7 thoughts on “Exploring the Best Solar Panel Choice for Your Home or Factory”